Food spoilage and the subsequent waste is costly. The convenience of a long shelf-life benefit all along the supply chain from farm to fork. Therefore, it is understandable that many start-up food manufacturers undergoing initial, or advanced, prototype development wish to extend the shelf-life of their product, for obvious reasons – today’s post-manufacture supply chains can be long and complex, and expensive too, especially if a cold chain is required. Thus, achieving a lengthy shelf-life at ambient temperature is many people’s dream! This also holds true for established food manufacturers, particularly when seeking new, more distant markets (especially in climate locations where temperature control is unreliable) or attempting to become a better proposition for selling in a physical, ‘brick and mortar’ store, where retailers wish to display for as long as possible to avoid price reductions due to food passing its Best Before date, hence cutting into their profit margin.

It is not uncommon to look at shelf-life extension or optimisation, largely in terms of the finished product. What can we do to the food to have it last longer? Process differently or include preservatives are the two most common thoughts that come to mind when people look at approaches to increase shelf-life, although more brand owners are considering reformulation as a way to lengthen shelf-life. Ultimately, reformulation should achieve one of two outcomes; I) provide some kind of an antimicrobial substance or II) alter the intrinsic conditions of the food such that the microorganisms cannot grow or grow more slowly. Natural antimicrobial substances, such as from the inclusion of botanical essential oils (Figure 1) or bacteriocins are examples of such antimicrobial substances that will exert a preservation effect.

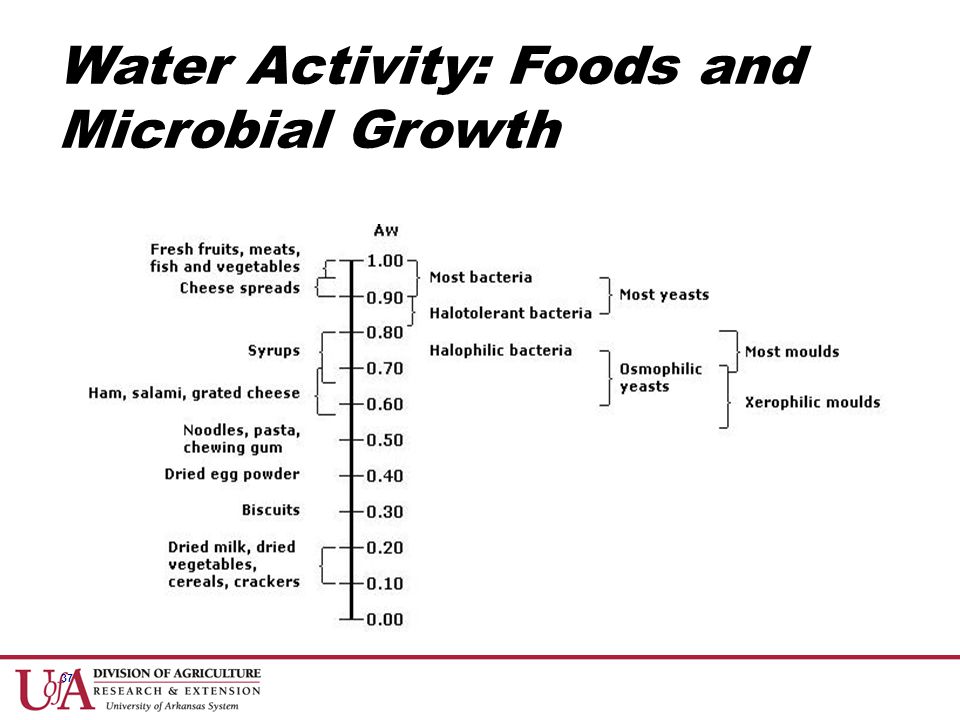

If we consider the intrinsic conditions, this is where are really getting back to basics, basic microbial physiology that is learn during introductory microbiology classes … meaning their are factors which govern microbial growth and if these factors cannot be met, the microbes cannot grow, it really is as simple as that. Examples of such factors are pH and water activity (Figure 2) and in turn, there are various ways to achieve these. Water activity for example, can be lowered through an increase in salts or sugars. Really though, the best indicators as to the shelf-life of a food and what is able to spoil it is pH and water activity. Temperature as an extrinsic factor (Figure 2) can then offer further shelf-life benefits.

Water activity is a concept that is sometimes misunderstood, yet plays an absolutely critical role in the shelf-life properties of a product. So what is water activity? Is it the same as moisture? Why is it even important? Let me delve into these a little – moisture is the water content overall, but within what is considered moisture, there is water bound to food molecules and the like and free water in the food product. It is this free water, and this free water only, that is available for microbial growth – it is measure on a scale between 0 (minimum) and 1 (maximum) (Figure 3). Therefore, the concepts of moisture (total water content) and water activity (amount of free water that is able to be used by microorganisms for their growth) are related but different. While moisture may give an indication of water activity, you cannot be sure, thus it is water activity, which is the definitive measure as to how much water is available in a food product to support growth of microorganisms.

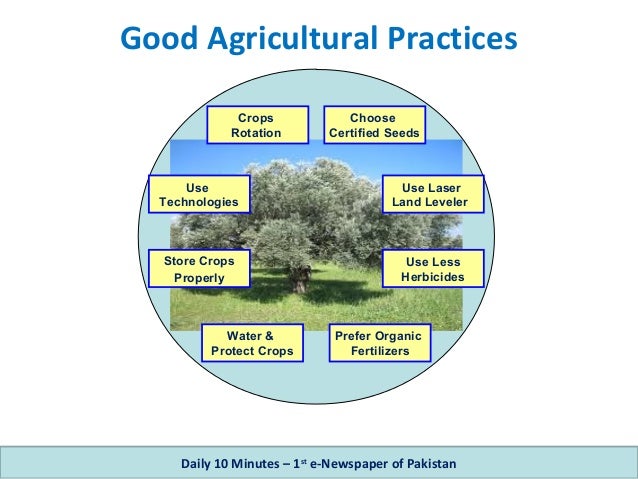

However, if one is really going to optimise shelf-life then a myriad of other factors come into play, right from farm to fork. While HACCP is the way that food safety risks can be managed and minimised, Good Agricultural Practices (GAP) during primary production (Figure 4) and Good Manufacturing Practices (GMP) during manufacture are key elements to ‘squeeze’ every possible amount of shelf-life out of a product. As a result, shelf-life optimisation needs to be considered in context of the entire agrifood farm to fork supply chain. There are not a lot of practices that many consider as impactful on shelf-life. As examples, farm hygiene, manufacturing environment design and airflow are some which might be forgotten as what needs to be considered to optimise one’s product’s shelf-life. Furthermore, practices of workers is key, as are Standard Operating Practices (SOPs), which may need to be reviewed and updated.

Thus, many, many factors come into play when looking extending or optimisation the shelf-life of a food product. It isn’t as straight-forward as changing processing conditions or adding in some preservatives. There’s no doubt that it is a complex process requiring painstaking consideration and analysis of primary production, your suppliers, transport, manufacturing environment, personnel, retail conditions and possible temperature and other abuse by consumers during domestic transport and storage. Therefore, knowing that these factors could be influential isn’t enough to optimise or extend shelf-life, it is vital to know how these factors could come into play in decreasing the shelf-life of your specific product.

Leave a Reply