By: Doreen Ting and Philip Button

Originally written by Ms Doreen Ting in 2008, with guidance from Dr Philip Button. Current update and partial rewrite by Dr Philip Button.

Food serves as a source of nutrition for humans and animals. However, it also serves as a substrate for the growth of microorganisms. The growth of microorganisms can be beneficial (for example, during production of fermented foods) as well as non-beneficial (growth in food leading to spoilage). Yeast (unicellular fungi) are undoubtedly the most important group of microorganisms exploited for commercial purposes, in particular bread making and the production of alcoholic beverages (Deak & Beuchat, 1996). To give an indication of the economic importance of wine to the Australian, data from Wine Australia (2019) show 63% of Australian wine is exported to a total value of $2.8 billion. However, yeast has also been a major concern in the food industry in terms of their ability to alter the quality of food products, hence impacting shelf life. The undesirable growth of yeast in some food products causes significant economic losses to the food industry. Deak & Beuchat (1996) state that yeast in general, are capable of growing in a wide range of foods under very specific environmental conditions, and under such conditions, metabolic activities of yeast may result in extensive economic losses to the food industry. Such conditions include 65-70% (w/w) sucrose, where the extremely low water activity results in very limited competition (Tokuoka, 1993). Spoilage of food products by yeast is detectable through odour or taste, in addition to physical changes. Therefore, in hopes of finding the best control method for these spoilage yeasts, one approach is adopting a “hurdle technology” concept such as the Hazard Analysis Critical Control Point (HACCP) system, which will be detailed in a subsequent part in this series.

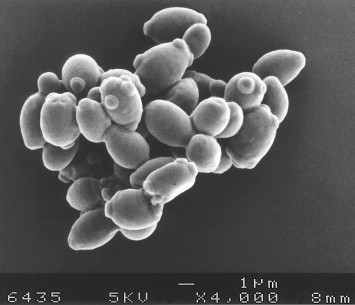

Yeast are certainly of special interest to food microbiologists due to the significant economical losses they cause to the food and beverage industry. This is especially so because they are able to grow in a wide range of food; high (syrups) to low (beverages) viscosity food, high sugar to high salt content food, and solid food such as fruits. These yeasts are characterised by their ability to not only survive, but thrive in environments hostile to many other microorganisms (Makdesi & Beuchat, 1996). While osmotolerance is generally recognised across this genus (El Halouat & Debevere, 1996), Malfeito-Ferreira (2019) says that Z. rouxii is recognised for its high-level osmotolerance while Z. bailii has a reputation for resistance to multiple normally lethal conditions, such as low pH, high organic acid concentration, preservatives and it also possess high osmotolerance. Its ability to tolerate stress conditions is of major concern to the food industry, and in fact Malfeito-Ferreira (2019) states that members of the Zygosaccharomyces genus are amongst the most “feared” spoilage organisms amongst manufacturers of high sugar and high acid products. Z. bailii (Figure 1) in particular, is recognised as “the most preservative-resistant organism known” (Stratford & Capell, 2003). Not only that, but stress cross protection has been observed in this species where exposure to a given preservative confers resistance to other preservative agents (Stratford et al., 2013). Furthermore, the fructose fermentation preference (typically producing acid and gas) of Z. bailii is a less common characteristic that can be exploited in its isolation from spoiled foods (Smittle & Flowers, 1982). These are major yeast contaminants, spoiling foods and beverages such as pickles, dried fruits (Verma & Joshi, 2000; Deak & Beuchat, 1996), mayonnaise (Kurtzman et al., 1971), fruit concentrates (Thomas & Davenport, 1985), soft drinks (Thomas & Davenport, 1985) and red wine (Malfeito-Ferreira, 2019).

Figure 1: Zygosaccharomyces bailii

Yeast have created undesirable properties in food products including off flavours and haze (Rodrigues et al., 2001) along with excessive carbon dioxide production (Zuehlke, 2003). Z. bailii is known to metabolise much aggressively compared to the other two species, Z. rouxii and Z. bisporus. This not only has caused spoilage of food but also has lead to explosion of canned and bottled foods and beverages on the shelf (Levya et al., 1999; Oda et al., 2006).

References

Deak, T & Beuchat, LR (1996). Handbook of Food Spoilage Yeasts, 1st edn, CRC Press, Boca Raton, FL, United States.

Kurtzman, C.P., Rogers, R., & Hesseltine, C. (1971). Microbiological spoilage of mayonnaise and salad dressings. Applied Microbiology 21 : 870-874.

Leyva, J.S., Manrique, M., Prats, L., Loureiro-Dias, M.C. & Peinado, J.M. (1999). Regulation of fermentative CO2 production by the food spoilage yeast Zygosaccharomyces bailii. Enzyme and Microbial Technology 24 : 270-275.

Malfeito-Ferreira, M. (2019). Spoilage Yeasts in Red Wines. In Red Wine Technology (pp. 219-235). Academic Press.

Oda, T., Furuta, M. & Inamasu, T. (2006). Bursting risk of capped PET bottles with leftover contents caused by yeast growth. Journal of the Food Hygienic Society of Japan 47 : 237-241.

Rodrigues, F., Corte-Real, M., Leao, C. & Dijken, J.P. (2001). Oxygen requirements of the food spoilage yeast Zygosaccharomyces bailii in synthetic and complex media. Applied and Environmental Microbiology 67 : 2123-2128.

Smittle, R.B. & Flowers, R.S. (1982). Acid tolerant microorganisms involved in the spoilage of salad dressings. Journal of Food Protection 45 : 977-983.

Stratford, M., Steels, H., Nebe-von-Caron, G., Novodvorska, M., Hayer, K., & Archer, D. B. (2013). Extreme resistance to weak-acid preservatives in the spoilage yeast Zygosaccharomyces bailii. International Journal of Food Microbiology 166 : 126-134.

Thomas, D.S. & Davenport, R.R. (1985). Zygosaccharomyces bailii – a profile of characteristics and spoilage activities. Food Microbiology 2 : 157-169.

Tokuoka, N. (1993). Sugar- and salt-tolerant yeasts. Journal of Applied Bacteriology 74 : 101-110.

Zuehlke, J. (2013). Influence of Zygosaccharomyces and Brettanomyces on Wine Quality and their Control During Vinification. PhD thesis, Washington State University.

Wine Australia. (2019). 2018: An impressive year for Australian wine exports. Market Bulletin, Issue 140. URL: https://www.wineaustralia.com/news/market-bulletin/issue-140 Accessed 30 December 2019.