This is an extract from my PhD thesis, passed by The University of Melbourne in 2008.

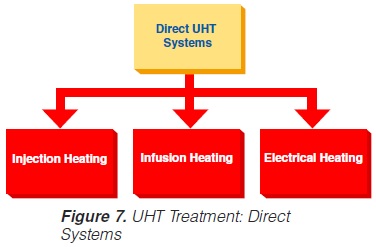

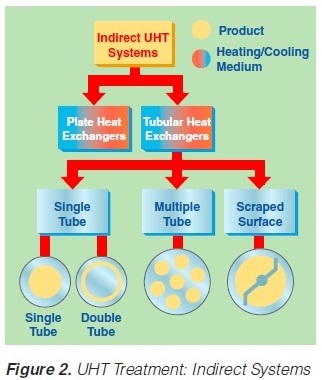

In the early 1950s, experimental UHT processing was underway in the United States (Tobias, 1955), while in Switzerland, UHT-type processing was introduced commercially in 1953 (Zadow, 1993a; 1998). Once the problem of aseptic filling had been addressed (Zadow, 1975), commercial UHT processing commenced in Australia around 1964 (Zadow, 1993a; 1998). This followed research and development around the world on aseptic processing since around the 1870s (Hostettler, 1972a). Two variations of UHT treatment are in use: direct (Figure 1) and indirect (Figure 2). A detailed description of these two techniques is provided by Datta et al. (2002) who also cover effects on milk while Jelen (1982) discusses both direct and indirect techniques from various perspectives of industrial relevance. The basis of the direct heating system is the direct mixing of steam with milk. This can be achieved in one of two ways: either steam injection, where steam is injected into the milk or steam infusion, in which milk enters an infusion chamber containing superheated steam. Indirect UHT treatment occurs when milk is heated by contact with steam or superheated water across the metal surface of a heat exchanger.

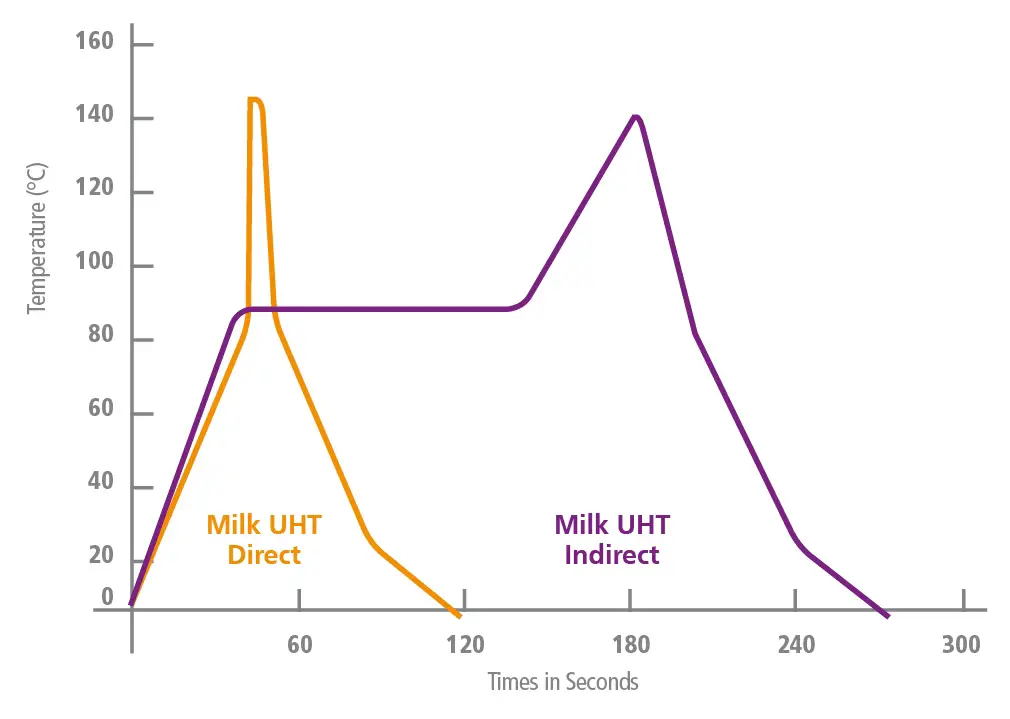

The major difference between the two forms of UHT treatment is the temperature profile during treatment (Figure 3), as outlined by Zadow (1986). Direct UHT treatment is less severe because an almost instantaneous rise and fall in temperature takes place with the milk held at a temperature between 70 and 80 °C for 70 seconds. In comparison, the increase and decrease in temperature in milk heated indirectly is considerably more gradual, therefore temperatures are elevated for a longer period, at or above 70 °C for 120 seconds and at or above 100 °C for 70 seconds. Severity of indirect heating is reflected by the degree of denaturation of whey proteins.Datta et al. (2002), who reviewed this topic, found substantial quantities of undenatured β-LG remaining in UHT milk that was treated by the direct method compared to the minimal amount typically seen in milk following indirect UHT treatment. These more recent results were not too different from the work of Zadow (1969) who observed more than twice the amount of β-LG denatured in UHT milk processed indirectly compared to that directly treated.

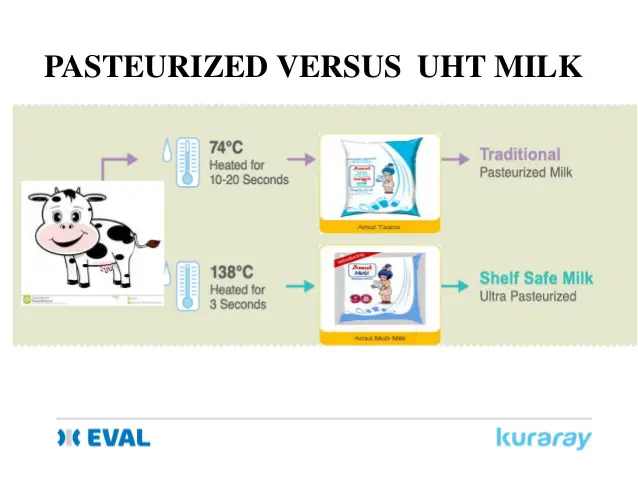

A myriad of nutritional and organoleptic changes have been observed in milk following UHT processing, some of which are unique to this product (Niroumand, 1977). Changes to proteins induced by ultra high temperature (UHT) processing can be detrimental to stability of UHT milk products. This is primarily due to formation of a complex between β-LG and the micelle surface proteins (predominately with κ-CN), in addition to interaction of β-LG with α-LA, which all occur at even moderate temperatures (Fairise et al., 1999), even as low as 80 ºC (Cho et al., 2003). Pasteurisation (Figure 4) is the most widely used heat processing method for raw milk, leading to reduction in numbers of spoilage bacteria and elimination of pathogenic bacteria. Higher temperatures (between 135 and 150 °C) can be applied for a (usually) shorter duration (between two and 20 sec) (Ahrné, 1988), for more effective control of bacterial contaminants. This form of heat processing is ultra high temperature (UHT) treatment which provides a very long shelf life, compared to pasteurised milk, even when stored at ambient temperatures. Such processing conditions give “commercial sterility”. This aspect is discussed by Luck (1975) and Zadow (1980) and implies that, theoretically, all microorganisms have been eliminated, but in practice this is not attainable and therefore commercial sterility is a measure of the failure rate (Dentener, 1986). Dentener (1986) also explains that processors usually strive for failure rate of no more than one in 5000.

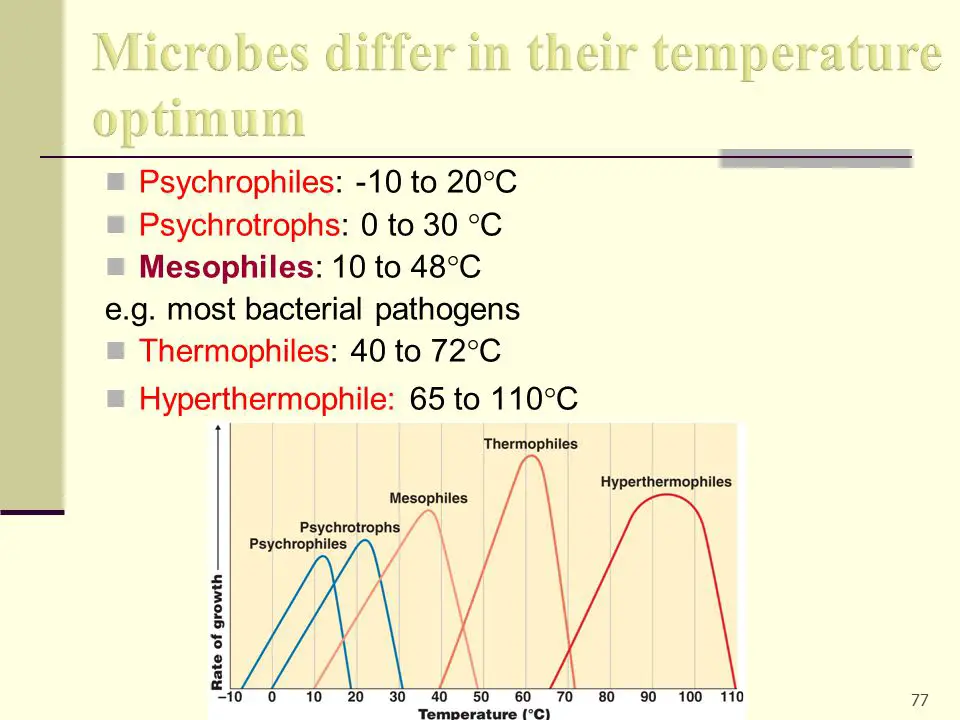

Mesophilic, psychrotrophic and psychrophilic microorganisms (Figure 5) are usually eliminated during UHT treatment; heat resistance enabling survival of these microorganisms is extremely unusual. However, spoilage is possible through the presence of mesophilic organisms in the finished product, which can also occur through contamination of the sterile product during filling For example, there is an isolated report of UHT milk spoilage due to growth of Enterobacter sp. and Micrococcus sp., which demonstrated remarkably high levels of heat resistance (Antoine & Donawa, 1990). It is possible that in this particular case time/temperature combination typical of the UHT process was not achieved. In some countries, contamination of UHT milk does appear to be a major problem. For example, in Egypt, some samples of UHT milk had a total bacterial count of up to 105 cfu/mL (El-Samragy et al., 1992).

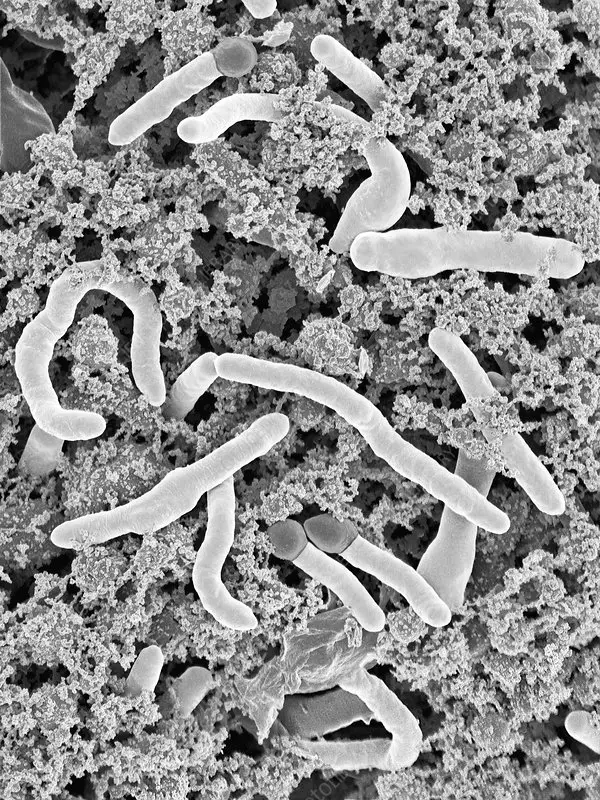

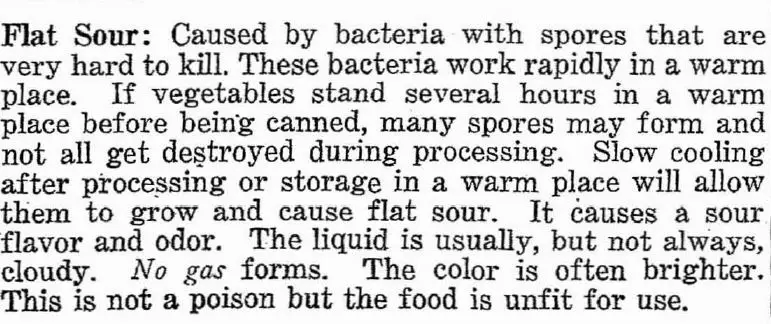

Due to the heat treatment conditions typical of UHT processing, thermophilic and thermoduric microflora or their spores are most often responsible for contamination of UHT milk (Foschino et al., 1990; Lewis, 1999). Although these bacteria are present in freshly drawn raw milk in low numbers (Flint et al., 2001), they may be present in long-life dairy products (Westhoff & Dougherty, 1981), and are very important owing to their potential involvement in spoilage of those products, which has been recognised for a long time (Grinstead & Clegg, 1955). Bacillus sporothermodurans has been one of the most frequently implicated (Klijn et al., 1997). As a result of the extreme heat resistance of its spores (Huemer et al., 1998), which may lead to the possibility of spore survival during UHT processing and subsequent germination in UHT milk (Pettersson et al., 1996), it can be regarded as one of the most important. Also, high levels of Geobacillus stearothermophilus vegetative cells (Figure 6) may cause flat sour spoilage (Figure 7) of low-acid foods, including milk (Ito, 1981), especially evaporated milk (Kalogridou-Vassiliadou et al., 1989). It is not unreasonable to expect one in 100 000 1 L packs of UHT milk to be contaminated with thermophilic or thermoduric bacteria, which is considered acceptable (Luck, 1975), although a total count of 102 cfu/mL after 15 d at 30 ºC also seems to be acceptable for UHT milk (Lewis, 1999), which would appear odd as this does seem significant contamination. Although many factors can be influential, the single most important factor in ensuring commercial sterility is a strict maintenance schedule (Farahnik, 1982).

Please note: To obtain the full reference details for the citations in this article, kindly access my PhD thesis online at my theses page on academia.edu