Heat treatment of food was a marvellous public health revolution. It enabled safe food to last longer and was an advancement from the early preservation methods of salting, smoking and the like. Despite the many advantages of thermal treatment of food, there are of course detrimental effects. For many decades, the advantages of heat preserving food outweighed the disadvantages. However, in the past 20-30 years, many non-thermal food processing technologies have emerged as commercially viable. This is despite many of these actually old technologies. One such technology is ozonation. Many technological advancements have enabled a wide range of different approaches to food preservation to come to the fore, another important reason is consumer-driven. That reason is indeed a driver of food trends and the fact that consumers increasingly want minimally processed foods that represent a ‘clean and green’ approach of sourcing and processing.

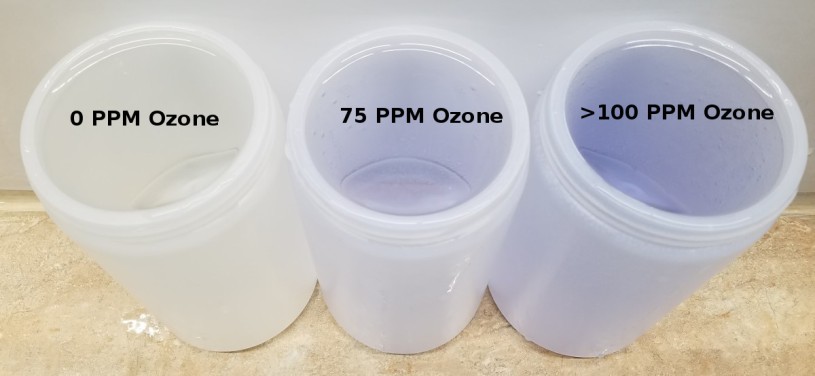

Ozone is another food processing technology that tends to be referred to as ’emerging’ or ‘innovative’ when in fact it is old technology. It is reported to have been first used for water treatment in 1893, in the Netherlands, and for food (meat) preservation in 1909, in Germany. Just to be clear at this stage that ozone is a gas, O3, which has one additional oxygen atom compared to molecules of oxygen, O2.

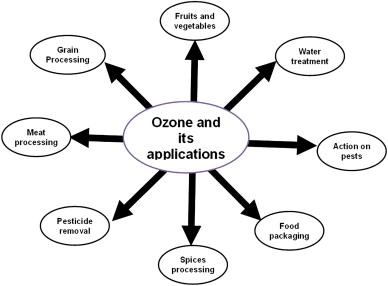

What can ozone be used for? It has wide applications in the food industry (Figure 1), and not only in food preservation:

- Ensuring microbiological safety of foods.

- Prevention of spoilage and extending shelf-life.

- Disinfection of water supplies.

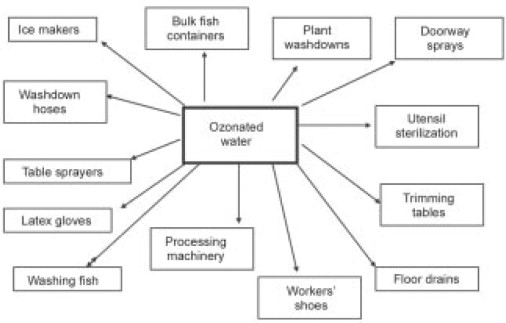

- Sanitisation of surfaces in food manufacturing facilities (Figure 2).

- Eliminating odours in food.

- Reducing the residual pesticides remaining on fresh produce.

What foods can ozone be used with/on? It’s more what foods that ozone is NOT compatible with! Ozone is very versatile indeed and can be used with these foods or types of products:

- Fresh or frozen foods.

- Fruits and vegetables.

- Red meat, poultry and seafood.

- Dairy foods.

- Spices.

- Beverages.

- Nuts.

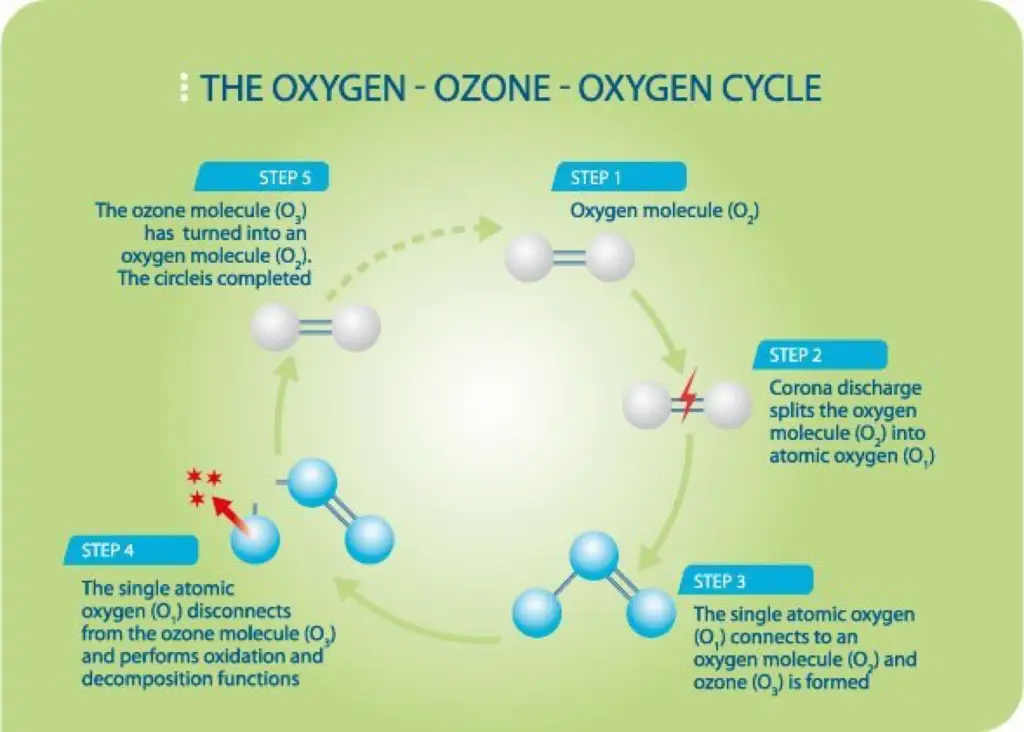

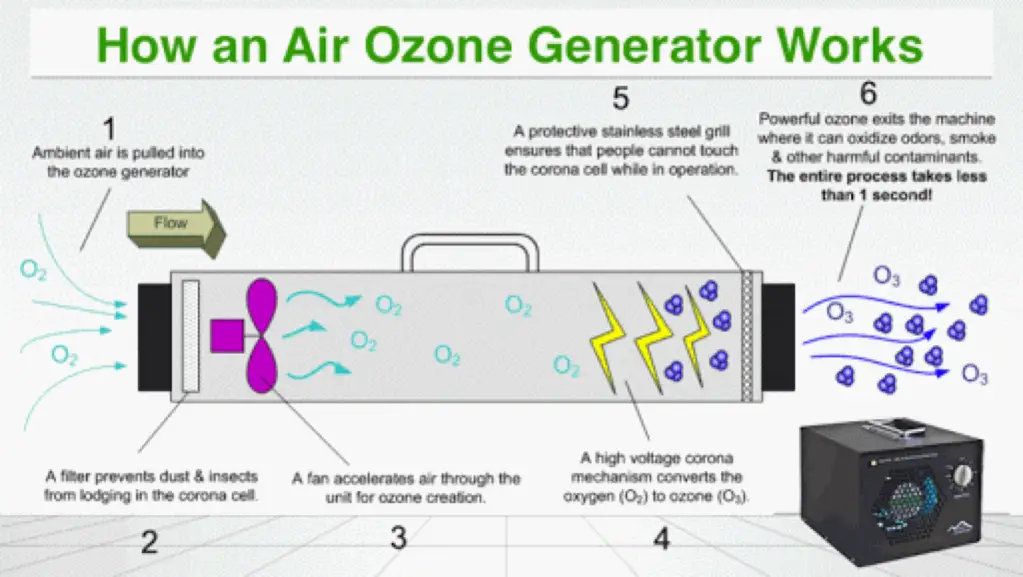

How is ozone formed? For ozone to form, air or ideally pure oxygen (for a higher yield when actually generating ozone) is necessary as the starting point (Figure 3) (Step 1). Energy is then required to split the oxygen molecule into individual atoms. This energy more often comes in the form of a corona discharge (Step 2). Once oxygen atoms are available, they are free to bond with any oxygen molecules that have not split, which forms ozone (Step 3). During its action, one of the oxygen atoms from the ozone molecule splits off (Step 4) and you have an oxygen molecule remaining (Step 5). This is another big advantage of this technology, no toxic/harmful end products, just simple and human-life-sustaining oxygen molecules.

How is ozone generated? The above paragraph outlines about how ozone is actually formed, but how about its actual commercial generation? As mentioned previously generation using energy from corona discharge is more common, as can be seen in Figure 4. At the start of the process we have oxygen molecules entering the system, either as air or pure oxygen. A fan blows the gas to the part of the unit where the high voltage corona discharge provides energy for disruption of the oxygen molecules to make individual oxygen atoms available. These oxygen atoms combine with oxygen molecules to form ozone.

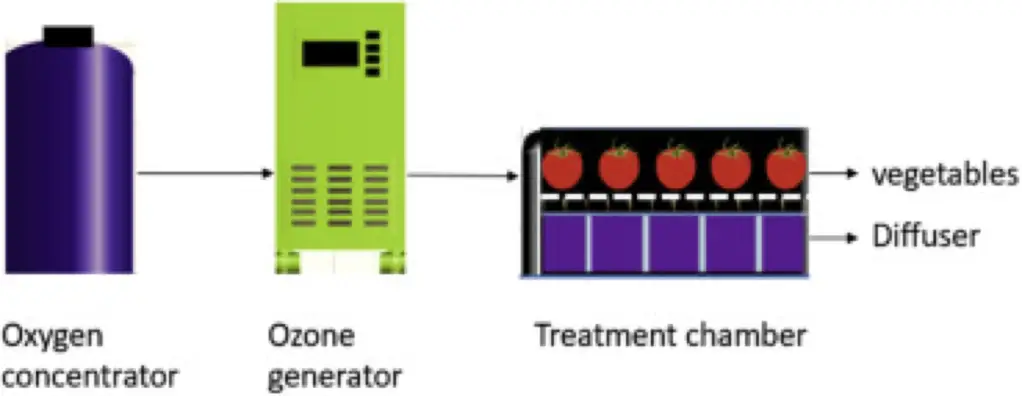

How can ozone be applied to food, water or surfaces? In either aqueous or gaseous forms. Where possible, the gaseous form would be preferred due to increased stability of the ozone compared to the aqueous form. These diagrams show the process of treating food with ozone. In each case, note that an ozone generator close by the treatment area is mandatory, due to the stability of ozone, even in the gaseous phase. In Figure 5 we have an example of how ozone can be applied to food when the ozone is diffused in water. To start the process the oxygen is concentrated before entering the generation unit. Next is the treatment chamber, where the generated ozone is physically combined with water, by one or two techniques, either venturi injection or fine bubble diffusion. Due to instability, immediate use of the ozonated water is a must.

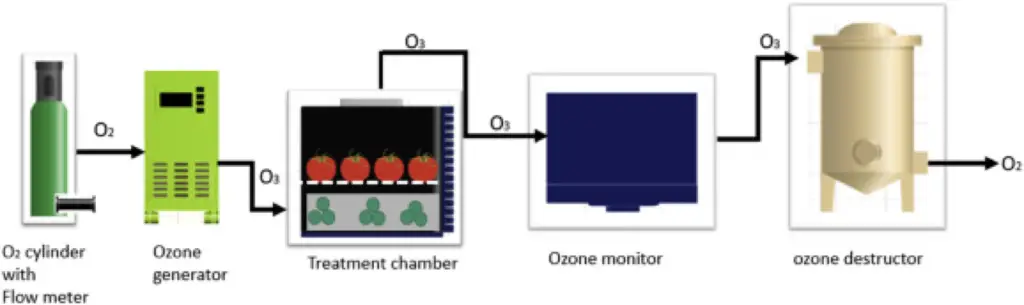

With the application of gaseous ozone to food, Figure 6 shows this process, where you have air or pure oxygen flowing into ozone generation unit, which then enters the treatment chamber for the gaseous treatment of the food. Now, although ozone degrades to oxygen gas after use, it is very important to be aware that ozone is a harmful gas, as a respiratory irritant at low concentrations or at high concentrations it can be fatal. Thus, monitoring of the amount of residual ozone remaining after treatment is necessary, then the passage of this output gas through an ozone destructor is required to ensure that no ozone remains and is emitted into the processing environment.

This is an overview of the technology, what it can be used for and how to use it.